-600x476.jpg)

-600x476.jpg)

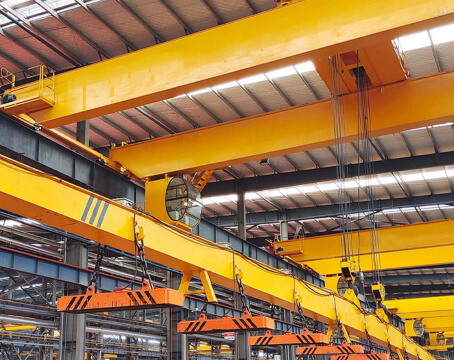

The iron and steel industry is one of the industries that use lifting cranes the most. Most of the lifting cranes in steel mills are production cranes, and there are not many requirements for high performance. However, the working environment of most cranes in steel mills is harsh, with high temperatures, high dust content, and sometimes corrosive gases. Therefore, the requirements for reliability and fault free rate are very strict. According to type classification, most steel mills use bridge cranes and gantry cranes. According to the classification of lifting appliances, steel plants have hooks, grab buckets, clamps, lifting electromagnet cranes, etc.

Iron and steel metallurgical crane is one of the important key equipment in the production of iron and steel enterprises. Due to the particularity of production activities in the iron and steel industry, higher requirements have been put forward for the reliability, safety and progressiveness of the metallurgical crane. The iron and steel crane industry as a whole is also developing according to this high requirement.

The QZ Grab double beam ovehead crane is a special type of crane that uses the grab as a lifting tool and can complete various special tasks such as loading, unloading, stacking, and transportation. Capable of handling heavier loads of up to 20 tons, suitable for lifting and handling bulk materials such as grain, ore, quartz powder, limestone, nickel, scrap metal, waste, blocks, coal, sand, other granular materials, and wood in warehouses and workshops of cement and coal yards. Widely used in steel mills, garbage treatment plants, mines, ports, railways, and power plants. Grab cranes have high requirements for high temperature, dust, and corrosive environments.

It mainly consists of a box bridge, a grab truck, a crane operating mechanism, a driver's cab, and an electrical control system. The lifting device is a grab.

The grab trolley is equipped with a lifting mechanism and an opening and closing mechanism, and the grab is wrapped with four steel wire ropes on the lifting and opening and closing drums respectively. The opening and closing mechanism drives the grab to close and grab materials. When the bucket mouth is closed, the lifting mechanism is immediately activated to evenly load the four steel wire ropes for lifting work. When unloading, only the opening and closing mechanism is activated, and the hopper opening immediately opens and tilts the material.

This type of product has a reasonable magnetic circuit distribution and a large magnetic penetration depth, and is designed specifically for lifting steel plates. The lifting operation is safe, fast, and accurate.

It adopts a fully sealed structure and is lightweight. The coil is subjected to vacuum drying and vacuum gluing treatment, which makes the insulation less prone to aging and has a long service life.

The rectangular lifting electromagnet generates a uniform magnetic field in the length direction, so even if the steel plate is bent, it can generate stable suction. If magnetic adjustment control is used at the same time, it can control the number of lifting steel plates.

The small diameter circular lifting electromagnet is designed specifically for lifting a steel plate.

Bending and deformation of steel plates during operation will affect installation and transportation. It is necessary to pay attention to the relationship between the length of the electromagnet (dimension A) and the thickness and width of the steel plate.

Considering the possible bending deformation during the lifting of long steel plates, which may affect safe handling, please use multiple lifting electromagnets when lifting long sized steel plates. For medium thick plates (6mm~32mm), the spacing between lifting electromagnets is usually 3-4 meters, and the length of the extended parts at both ends can be taken as half of the spacing.

The electromagnetic bridge crane is equipped with a detachable electromagnetic disc, which is particularly suitable for heavy loading and unloading of magnetic ferrous metal products and materials (such as steel ingots, section steels, pig iron blocks) in fixed bays indoors or outdoors in metallurgical factories.

It is also commonly used in mechanical factories and warehouses to transport materials such as steel, iron blocks, scrap iron, scrap steel, iron filings, etc. The electromagnetic bridge crane for lifting equipment belongs to the heavy class (A6) working system, and the crane includes the self weight of the electromagnetic disc. This machine consists of five parts: a box shaped bridge, a crane operating mechanism, a small car, electrical equipment, and an electromagnetic disc.

All mechanisms are operated in the control room and are equipped with rainproof equipment when used outdoors. The basic structure of the electromagnetic bridge crane for lifting equipment is the same as that of the hook bridge crane, except that a DC lifting electromagnet (also known as an electromagnetic suction cup) is hung on the hook to lift magnetic conductive black metal and its products. Usually, the AC power is converted into DC power through an electric generator set installed on the bridge platform or a thyristor DC box installed in the driver's cab. Then, the DC power is sent to the lifting electromagnet through a flexible cable through a dedicated cable drum installed on the trolley frame.

Main features:

The U series four-rope grab is mainly used with bridge or gantry cranes with two sets of lifting drums to grab all kinds of loose deposits, load, unload, turn the pile and other operations.

The U series four-rope grab consists of a brace, a jaw plate and a beam. The picking action of the four-rope grab is controlled by the lifting drum and the opening and closing drum on the crane. The ends of the two wire ropes wound on the lifting drum are fixed on the wedge shell of the head of the grab bucket, and the wedge shell is hinged with the head of the grab bucket. When the lifting drum rotates, the wire rope drives the grab bucket up and down through the wedge shell; The two wire ropes wound on the opening and closing reel are wound between the head of the grab bucket and the pulley of the beam through the guide wheel to control the opening and closing of the grab bucket. When taking materials, the grab drops to the pile in an open state (the opening and closing drum does not move at this time), and the lifting direction starts the opening and closing drum (the lifting rope does not move). Under the action of the weight of the grab bucket, the grab jaw plate digs into the material, and after the grab bucket is completely closed, the lifting drum and the opening and closing drum are started at the same time to raise the loaded grab bucket to a certain height, and the crane moves the grab bucket to the unloading position. Start the opening and closing drum in the downward direction (the lifting drum does not move), and open the grab bucket for unloading

Under the action of the weight of the grab bucket, the grab jaw plate digs into the material, and after the grab bucket is completely closed, the lifting drum and the opening and closing drum are started at the same time to raise the loaded grab bucket to a certain height, and the crane moves the grab bucket to the unloading position. Start the opening and closing drum in the downward direction (the lifting drum does not move), and open the grab bucket for unloading.

Free Crane Solution

Providing standardized and specification-compliant products.

Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

Technical Support

Our engineers and technical experts can provide professional advice on the selection, performance optimization, safety, and cost-effectiveness of crane equipment.

Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

Providing production drawings and design blueprints.

One-Stop Supplier

We provide over 200 types of cranes and their related products, saving customers’ purchasing time.

18-month Warranty

All products come with an 18-month warranty period.

Replacement of damaged components (non-human-induced) is provided during the warranty period.

Provide Crane Parts Replacement/Upgrades

We provide replacement for all types of crane parts and associated products, whether purchased from our company or not.

QD model Double Girder Overhead Crane is applied in open warehouse or rail sideways to conduct common loading unloading and material handling works.

QZ Type Grab Bridge crane is widely used in loading goods in port, factory, workshop and power plant.

Multi-petal (orange-petal) type: mainly used with single-hook cranes for grabbing domestic garbage, scrap steel and other materials, often used in environmental protection power plants, steel plants, etc.