The explosion-proof electric single girder crane is designed and manufactured according to the standard JB/T10219-2000, and is used with electric hoists in the form of B, BM, BCD, BM, BM, etc., to become a light and small crane with rail travel. The lifting capacity is 1~10 tons, the applicable span is 7.5-22.5 meters, and the working environment temperature is in the range of -20°C-+40°C.

1. Metal Structures

The main beam is rolled into a U-shaped channel steel with a steel plate, and then welded into a box-shaped solid web beam with the I-beam, and the beam is also rolled into a U-shaped channel steel with a steel plate, and then welded into a box-shaped beam, which is convenient for storage and transportation, and the main beam is connected with M0 bolts (high-strength bolts) and becomes a whole.

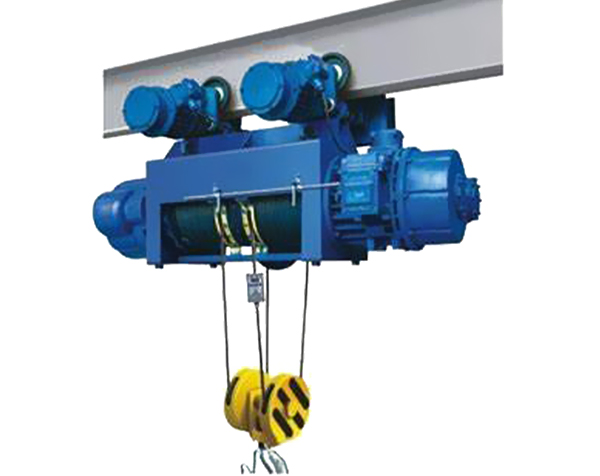

2. Explosion-proof electric hoist

The explosion-proof electric hoist can lift heavy objects and move longitudinally along the main beam.

3. Operating mechanism

The explosion-proof electric single girder crane is driven separately, the drive and braking are completed by the flameproof conical rotor three-phase asynchronous motor, and the transmission is a "one open and one closed" gear transmission, and the closed gear part borrows the reducer of the 5-ton hoist running trolley part.

4. Electrical equipment

The running motors used in the explosion-proof electric single girder crane include single and two-speed flameproof conical rotor motors (used for running speeds of 10 and 20 m/min, and other special speed requirements can be specially designed for users) with different control forms, equipped with two kinds of electrical control, electric hoist and the whole crane are equipped with safety devices, such as lifting limit switches, end limit switches, etc.

Scrap plants play an important role in the processing and recycling of waste materials, and choosing the right crane is key to ensuring efficient

A bridge crane, also known as an overhead crane, is a type of material handling equipment used for lifting and moving heavy loads in various industrial settings.

Enhanced Load Capacity: KE Crane has increased the load capacity of its bridge cranes to handle the heavy and irregularly shaped materials commonly found in scrapyards.