-600x476.jpg)

-600x476.jpg)

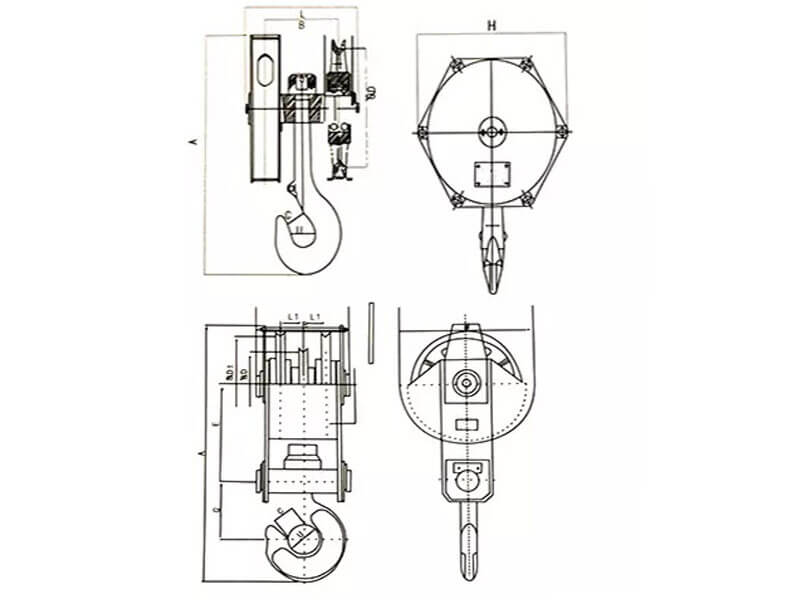

Crane hooks are very critical components in lifting machinery, which are usually classified according to the materials used, manufacturing processes, uses, and other factors.

Different types of crane hooks may differ in shape, production process, operation mode or other characteristics. Different types of crane hooks are usually able to meet different usage needs, load ratings, sizes and category requirements.

Common crane hook types:

Single hook and double hook

Forged hooks and sandwich hooks

Closed and semi-closed hooks

Electric rotary hook

1.Single hook and double hook

The main difference between these two types is the number of hooks

(1) Single hook

When the lifting load does not exceed 75 tons, it is suitable for single hook, which is simple and easy to use.

(2) Double hook

When the lifting load exceeds 75 tons, it is suitable to choose double hooks, and the bearing capacity is relatively higher.

2.Forged hooks and sandwich hooks

The biggest difference between forged hooks and sandwich hooks is the way they are manufactured.

(1) Forged hooks

Forged hooks are forged from a single piece of high-quality, low-carbon steel, and after slow cooling, the hook achieves good stress resistance (usually in the range of 16Mn to 36MnSi).

(2) Sandwich hooks

They are manufactured in a slightly more complex way than forged hooks and are manufactured from several steel plates riveted together for relatively higher stress resistance and safety performance. Even if some parts of the hook are damaged, it will continue to operate. The user can choose to use a single or a pair of sandwich hooks according to their needs.

3.Closed and semi-closed hooks

When users need to consider matching hooks with accessories, they can choose enclosed and semi-enclosed crane hooks to ensure a smooth and safe hoisting process.

(1) Closed hooks

Accessories for enclosed crane hooks are less easy to use and more time-consuming, but they are also relatively safer and more load-bearing.

(2) Semi-closed hooks

This hook is safer than a standard hook and is easier to install and remove than a closed hook.

Electric rotary hook

Electric rotary hook is a precision equipment that can improve the mobility and work efficiency of the crane in the process of container lifting and transportation. These hooks also keep the cargo stable when rotating during work, making them easy to operate and quite efficient, even when moving multiple containers at the same time in a confined space.

With its small installation space, easy maintenance, reliability and low cost, cable reels have replaced conductor lines and become the mainstream solution in the field of mobile transmission (power, data and fluid media).

The hook is a commonly used lifting device and is widely used in lifting machinery.

Metallurgical cranes are widely used in steel mills and are important machinery and equipment in the steelmaking process. Compared with ordinary bridge cranes, metallurgical cranes are characterized by a high-temperature operating environment, which poses a high challenge to the operators and the safety management of the equipment.