Description

Motor cable reel is a winding device used for large mobile starting equipment to transmit power, control power, or control signals between two relatively moving bodies. It is widely used in heavy machinery equipment such as port gantry cranes, container cranes, ship loaders, tower cranes, and other similar working conditions.

Features

1. The main engine is composed of a gearbox, a power head, and a collector slip ring box as a whole. The power head consists of an electric motor, a hysteresis coupling, and a planetary gearbox. According to different working conditions, single or multiple power heads can be used as the driving force for the hysteresis cable reel. The collector slip ring box is the power (signal) transmission part, which can be divided into power transmission and signal transmission according to its purpose, and can be divided into 500V, 3KV, 6KV, 10KV, 20KV, etc. according to voltage levels.

2. The cable winding part is the cable winding part, which can be divided into multi row winding and single row winding. For the convenience of transportation, the reel with a diameter of ≤ 2.6m is a complete structure; The reel with a diameter greater than 2.6m has two semi-circular structures that are assembled on-site by the user.

3. The working principle of a hysteresis coupling is to use magnetic principles to combine the active and passive magnetic half pairs into a pair of magnetic pairs, and transmit torque through non-contact magnetic coupling. One of the magnetic half pairs is a disk composed of permanent multipole magnetic steel, while the other half pair is a strong magnetic induction disk. When the motor drags one of the magnetic half pairs to rotate at high speed, once there is a speed slip between the two disks, the multipole disk will alternately magnetize the opposite induction disk, generating a torque that resists this slip. This is the magnetic non-contact coupling between the two disks, So as to drag (or brake) the disk to rotate. Adjusting the air gap between magnetic pairs can adjust the damping torque. When the air gap distance is locked, the damping torque during operation can remain constant for a long time and does not change with the relative speed of the active and passive components. Based on the special torque coupling function of the hysteresis coupling, it can achieve constant torque, so the cable reel can achieve ideal winding characteristics, making it a suitable equipment for winding cables.

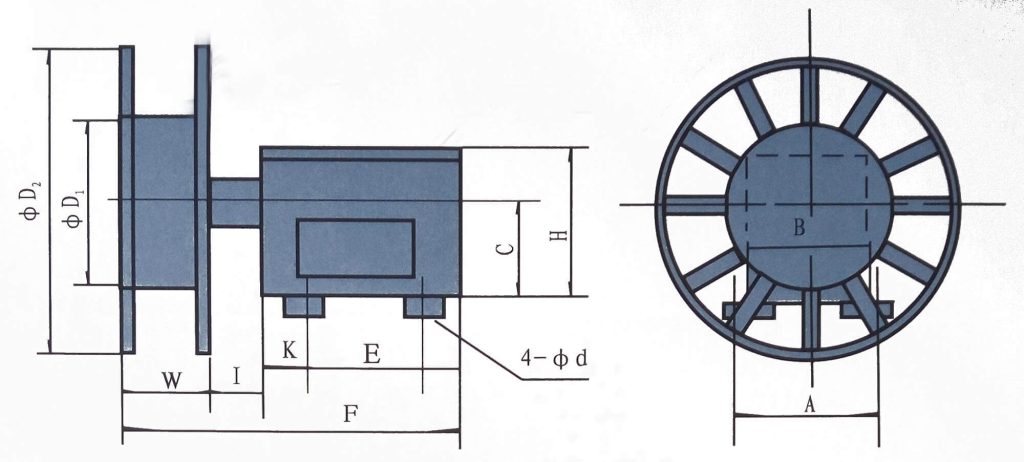

Technical Data

|

Size Outline No. |

A |

B |

C |

D1 |

D2 |

F |

E |

d |

H |

I |

K |

W |

Weight/kg |

|

1 |

665 |

575 |

625 |

1000 |

1800 |

1600 |

750 |

26 |

805 |

80 |

60 |

380 |

830 |

|

2 |

2000 |

840 |

|||||||||||

|

3 |

2200 |

860 |

|||||||||||

|

4 |

1500 |

2300 |

1650 |

430 |

930 |

||||||||

|

5 |

2500 |

980 |

|||||||||||

|

6 |

2600 |

1000 |

|

Cable type |

Allowable current/A(40℃) |

50m series |

Outline No. |

100m series |

Outline No. |

150m series |

Outline No. |

200m series |

Outline No. |

|

|

100% |

50% |

|||||||||

|

YC3X25+1X10 |

90 |

120 |

/ |

/ |

JDD120-100-4 |

1 |

JDD120-150-4 |

2 |

JDD120-200-4 |

4 |

|

YC3X35+1X10 |

110 |

150 |

/ |

/ |

JDD150-100-4 |

JDD150-150-4 |

JDD150-200-4 |

|||

|

YC3X50+1X16 |

140 |

180 |

JDD180-50-4 |

1 |

JDD180-100-4 |

2 |

JDD180-150-4 |

4 |

JDD180-200-4 |

5 |

|

YC3X70+1X25 |

180 |

220 |

JDD220-50-4 |

JDD220-100-4 |

JDD220-150-4 |

JDD220-200-4 |

Applications

Motor cable reel is a winding device used for large mobile starting equipment to transmit power, control power, or control signals between two relatively moving bodies. It is widely used in heavy machinery equipment such as port gantry cranes, container cranes, ship loaders, tower cranes, and other similar working conditions.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)