Description

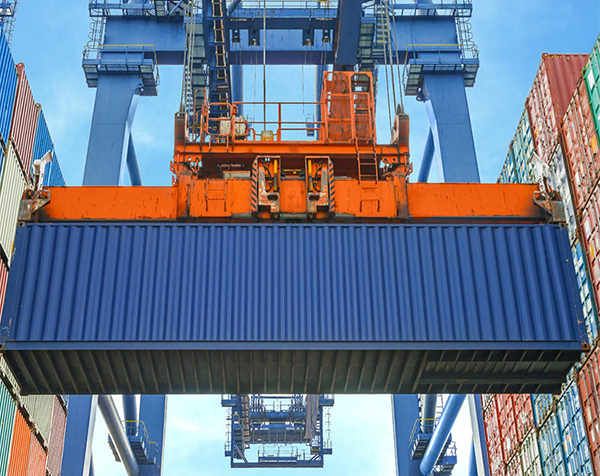

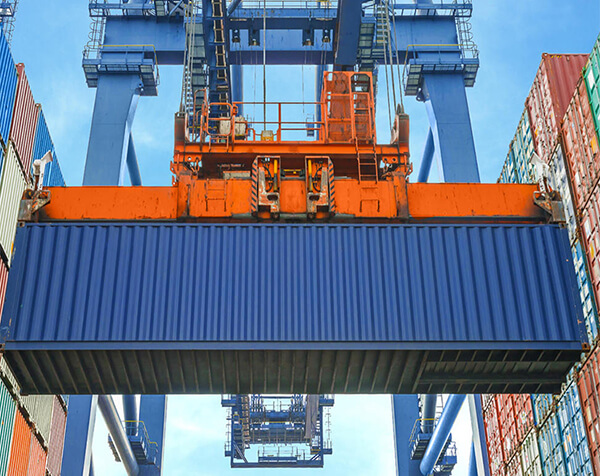

Container spreader can lifting twin 20ft containers at the same time. It made of hanger structure, rotary lock device, guiding device, a telescopic device and hydraulic system, with orientation alignment, automatic opening and locking, automatic telescopic function, in order to work quickly and accurately to container loading and unloading. The sling is provided with a mechanical or hydraulic telescoping mechanism, in20ft to45ft range expansion, in order to adapt to different specifications of container handling requirements. Guide device has a fixed guide plate and belt turning plate two, to achieve the spreader is positioned, with fixed guide spreader used for tire type gantry crane, rail type gantry crane for loading and unloading machinery, and with automatic turning plate (4 of each turning plate can be controlled separately) of the spreader is generally applied in the shore container cranes.

Features

- Efficiency: Container lifting equipment can quickly and efficiently load and unload containers, reducing loading and unloading times and increasing productivity.

- Safety: These devices typically come with various safety features such as overload protection, anti-tilt systems, and emergency shutdown mechanisms to ensure operational safety.

- Flexibility: Container lifting equipment can be used for various types and sizes of containers, ranging from 20-foot to 40-foot containers, as well as special container types like flatbed and refrigerated containers.

- Labor Savings: Using container lifting equipment can reduce manual labor, thus lowering labor costs and reducing the risk of personnel injuries.

- Remote Operation: Some modern container lifting equipment can be operated remotely, making operations safer and more convenient.

- Reduced Cargo Damage: Container lifting equipment can precisely control the movement and placement of cargo, reducing the risk of damage during loading and unloading.

- Improved Container Stacking Efficiency: Container lifting equipment can efficiently stack containers, saving storage space in container yards.

Technical Data

|

Container Spreader Technical Specifications |

|||

|

For operation with ISO standard 20’,40’, 45’ and twin 20’ containers |

Control voltage |

AC 380V/50HZ DC 24V(as agreed) |

|

|

Total power |

~8KW |

||

|

SWL (Concentric/ Single mode) |

40T |

Precaution class |

IP 55 |

|

SWL (Eccentricity / Twin 20’ mode) |

65T |

Operating pressure of the system |

120bar |

|

Load of lifting lugs at four corner |

19.5t×4 |

Ambient temperature |

-20℃ ~+55℃ |

|

Self-weight (spreader) |

~13t |

Twist lock Mode |

ISO floating twist lock, driven by an oil cylinder |

|

Expansion time (20’to 45’) |

~ 30 S |

Telescopic Mode |

The telescopic system is driven by means of a hydraulic motor and reduction gearbox connected to an endless chain. |

|

Twist lock rotation 90° |

~ 1 S |

||

|

Flipper through 180° |

5~7S |

Flippers Device |

The flippers are drived by hydraulic |

|

Power voltage/ Frequency |

AC 380V (3P)/50HZ |

Application |

Portal crane, Jib crane, QC, RMG, RTG |

|

Operating mode |

Control box with touch screen and Application Wireless remote |

Electric Control |

SIEMENS / Schneider |

Applications

Container crane is a type of machinery and equipment widely used in various fields such as logistics transportation, ports and docks. Through the control of the lifting mechanism, it achieves multiple actions such as lifting, moving, and transferring containers. It can improve the efficiency of logistics transportation, reduce the consumption of human resources, and meet the diverse needs of the market.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)