Description

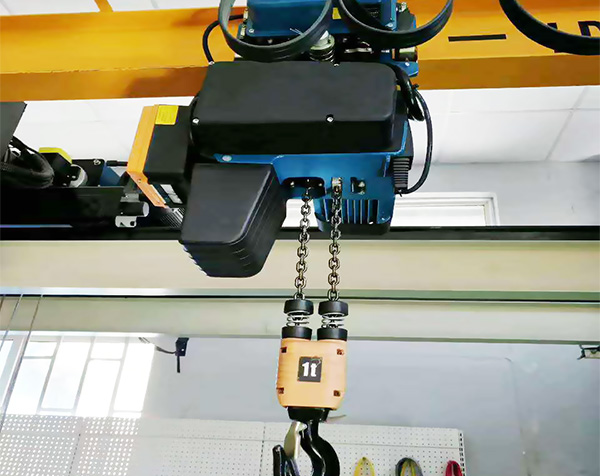

European electric chain hoist has compact structure and reliable performance. Modular design enables our products to flexibly form different lifting tonnage, lifting speed and working level systems. Excellent performance meets the requirements of rapid cargo transfer and precision assembly, and can also be widely used in places with complex use requirements to meet the personalized needs of customers. Standardized and user-friendly design greatly reduces maintenance costs and improves operating performance. The main components are maintenance-free and do not need to be replaced during use, which complies with safety regulations.

Features

- New minimalist design

- Completely sealed body

- New die-cast aluminum housing

- Low deadweight

- High-efficiency motor, high-efficiency transmission

- Maintenance-free design

- Safe and reliable, high working efficiency

Technical Data

| Model | Load(KG) | Lifting speed (m/min) |

Motor power (kw) |

Motor speed (r/min) |

Operating voltage (V) |

Control voltage (v) |

Working class (FEM/ISO) |

| BMS0.125-01M | 125 | 8/2 | 0.4/0.1 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS0.125-01M | 125 | 16/4 | 0.8/0.2 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS0.25-01M | 250 | 8/2 | 0.4/0.1 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS0.25-01M | 250 | 12/3 | 0.8/0.2 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS0.25-01M | 250 | 16/4 | 1.8/0.45 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS0.5-01M | 500 | 8/2 | 0.8/0.2 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS0.5-01M | 500 | 12/3 | 1.8/0.45 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS0.5-01M | 500 | 24/6 | 2.3/0.6 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS0.5-01M | 500 | 16/4 | 2.3/0.6 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS0.5-02M | 500 | 4/1 | 0.4/0.1 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS01-01M | 1000 | 12/3 | 2.3/0.6 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS01-01M | 1000 | 8/2 | 1.8/0.45 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS01-01M | 1000 | 6/1.5 | 1.8/0.45 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS01-02M | 1000 | 4/1 | 0.8/0.2 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS01-01M | 1000 | 16/4 | 3.6/0.9 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS1.6-01M | 1600 | 12/3 | 3.6/0.9 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS02-01M | 2000 | 8/2 | 3.6/0.9 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS02-02M | 2000 | 4/1 | 1.8/0.45 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS02-01M | 2000 | 6/2 | 3.6/1.2 | 1440/480 | 220-460 | 24 | 2M/M5 |

| BMS2.5-01M | 2500 | 8/2 | 4/1 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS2.5-01M | 2500 | 6/2 | 4/1.3 | 1440/480 | 220-460 | 24 | 2M/M5 |

| BMS2.5-01M | 2500 | 4/1.35 | 4/1.3 | 1440/480 | 220-460 | 24 | 2M/M5 |

| BMS3.2-02M | 3200 | 4/1 | 3.6/0.9 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS3.2-02M | 3200 | 6/1.5 | 4/1 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS3.2-02M | 3200 | 3/1 | 3.6/1.2 | 1440/480 | 220-460 | 24 | 2M/M5 |

| BMS05-02M | 5000 | 4/1 | 4/1 | 2880/720 | 220-460 | 24 | 2M/M5 |

| BMS05-02M | 5000 | 3/1 | 4/1.3 | 1440/480 | 220-460 | 24 | 2M/M5 |

Options And Components

Applications

It is widely used in machinery manufacturing, automobile manufacturing, aircraft manufacturing, shipbuilding industry, railway transportation, food production, electricity, energy and other industries to help people easily complete heavy lifting operations.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)