Description

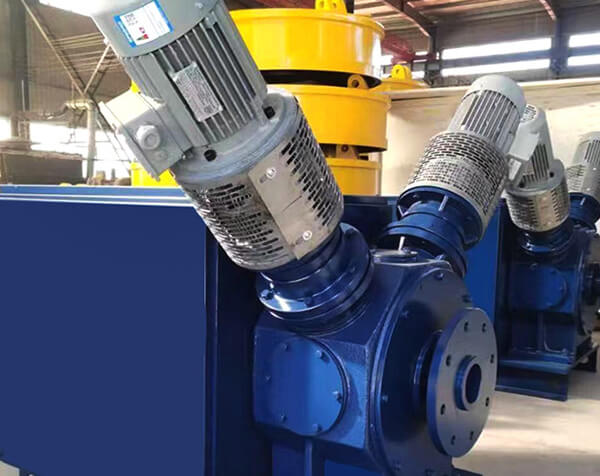

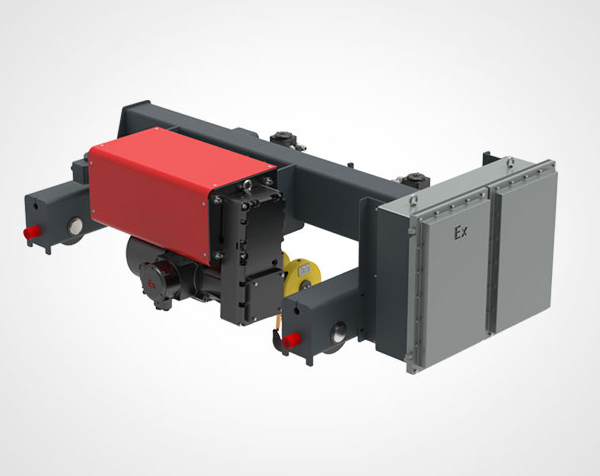

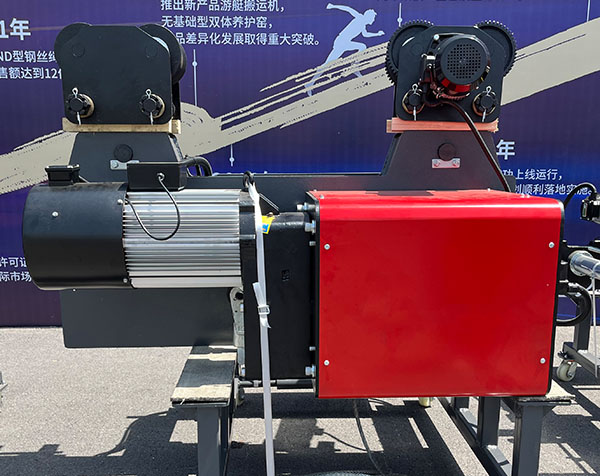

Explosion-proof hoists are widely used in important industries such as ports, electricity, shipbuilding, petrochemicals, railways, industrial control, highways, large-scale transportation, pipeline laying, shaft management and protection, maritime rescue, marine engineering, airport construction, bridges, aviation, venues, and mechanical equipment for infrastructure projects. The explosion-proof grades of explosion-proof electric hoists are dⅡBT4 and dⅡCT4, respectively, and the structure is reasonable. The leaking parts of explosion-proof wire rope electric hoists are made of special spark-free materials, and the explosion-proof performance is safe and reliable.

Features

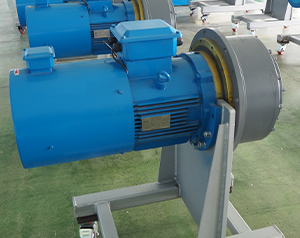

- The explosion-proof electric hoist is composed of several parts that can be disassembled separately, which is very convenient to use, maintain and repair, and can shorten the repair cycle.

- Its explosion-proof motor and explosion-proof control box are separate explosion-proof structures. The control button, limit switch, and explosion-proof lifting weight limiter all meet the corresponding explosion-proof requirements.

- The parts are highly common and interchangeable.

- Steady operation, flexible structure, high explosion-proof grade.

Technical Data

| Model | HB. BCD, BMD | |||||||

| Lifting capacity(t) | 0.5 | 1 | 2 | 3 | 5 | 10 | 16 | 20 |

| Lifting height(m) | 6/9/12/18/24/30 or specified height | |||||||

| Lifting speed(m/min) | 8 (0.8/8) | 7 (0.7/7) | 3.5 (0.35/3.5) | |||||

| Traveling speed(m/min) | 20 | |||||||

| Power Source | 3PAC 380v,50HZ | |||||||

Options And Components

Applications

It is widely used in ports, electric power, shipbuilding, petrochemical, railways, industrial control, highways, large-scale transportation, pipeline laying, well management and protection, maritime rescue, marine engineering, airport construction, bridges, aviation, venues and other important industries as well as mechanical equipment of infrastructure projects.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)