Description

The low-headroom chain electric hoist is a lifting tool specially designed for low-rise factories. Compared with ordinary electric hoists, it has ultra-low headroom dimensions. The distance between the upper and lower hooks is lower than that of ordinary electric hoists, and the hook can be raised to the bottom of the track, shortening the distance between the machine body and the beam track, greatly increasing the lifting height. Therefore, it is suitable for use in low-rise factories and other work environments with strict requirements on the lifting height.

Features

1.Body shell: Made of all-aluminum material, it greatly improves the corrosion resistance and heat dissipation effect of the hoist.

2.Safety clutch: It has a built-in safety clutch. The clutch produced by our company is our company's independently developed anti-friction clutch, which plays a protective role.

3.Brake: The unique current electromagnetic brake structure has a strong braking force to ensure the braking requirements during use.

4.Gear: The low-noise helical gear design reduces the noise during operation.

5.Push button switch: The push button switch used by our company is waterproof, light and durable.

6.Designed for large tonnage loads, due to lifting large equipment and components. Lightweight aluminum alloy shell, good heat dissipation, fully enclosed design, protection level IP54. Equipped with phase sequence protection device to prevent accidents caused by wrong power connection.

7.Three 220/380/440V voltages are optional to meet the power plug requirements of different countries. The upper and lower limit devices of mechanical gear transmission are safe, reliable and sensitive.

8.Low voltage control circuit and control switch to prevent the danger of high voltage leakage.

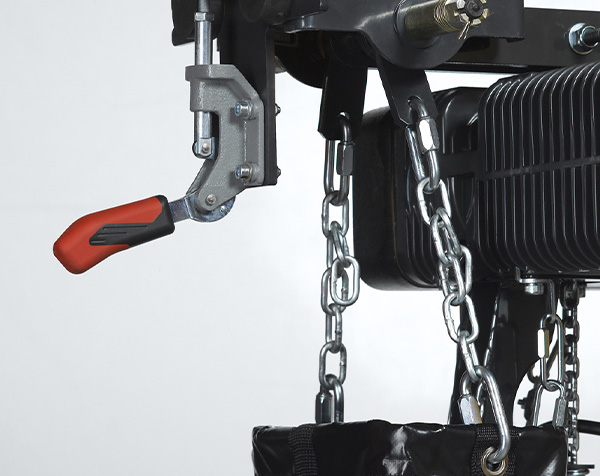

9.Forged and heat-treated hooks are equipped with safety tongues. The pulley hook is assembled with bearings and chain guides to make lifting operations smoother.

Technical Data

| Type | Rated lifting capacity T |

Lifting speed m/min |

Hook gague mm |

I-beams mm |

Lifting motor | Operating motor | Number of chain loops | Chain specifications | Test load T |

Net weight KG |

||||||

| Power KW |

Rotate speed r/min |

Phase P |

Voltage V |

Frequency Hz |

Power KW |

Rotate speed r/min |

Running speed m/min |

|||||||||

| WBH-00501SL | 0.5 | 6.8 | 440 | 60-190 | 0.75 | 1440 | 3 | 200-460 | 50/60 | 0.4 | 1440 | 11/21 | 1 | Ф6.3 | 0.625 | 0.81 |

| WBH-01001SL | 1 | 6.6 | 480 | 60-190 | 1.5 | 1440 | 3 | 200-460 | 50/60 | 0.4 | 1440 | 11/21 | 1 | Ф7.1 | 1.25 | 1.1 |

| WBH-02001SL | 2 | 6.6 | 570 | 82-228 | 3.0 | 1440 | 3 | 200-460 | 50/60 | 0.4 | 1440 | 11/21 | 1 | Ф10.0 | 2.5 | 2.3 |

| WBH-02002SL | 2 | 3.3 | 535 | 82-228 | 1.5 | 1440 | 3 | 200-460 | 50/60 | 0.4 | 1440 | 11/21 | 2 | Ф7.1 | 2.5 | 2.2 |

| WBH-03001SL | 3 | 5.4 | 640 | 82-228 | 3.0 | 1440 | 3 | 200-460 | 50/60 | 0.75 | 1440 | 11/21 | 1 | Ф11.2 | 3.75 | 2.8 |

| WBH-03002SL | 3 | 4.4 | 685 | 82-228 | 3.0 | 1440 | 3 | 200-460 | 50/60 | 0.75 | 1440 | 11/21 | 2 | Ф10.0 | 3.75 | 2.8 |

| WBH-05002SL | 5 | 2.7 | 740 | 100-256 | 3.0 | 1440 | 3 | 200-460 | 50/60 | 0.75 | 1440 | 11/21 | 2 | Ф11.2 | 6.25 | 5.6 |

| WBH-07503SL | 7.5 | 1.8 | 890 | 100-256 | 3.0 | 1440 | 3 | 200-460 | 50/60 | 0.75 | 1440 | 11/21 | 3 | Ф11.2 | 9.4 | 8.4 |

| WBH-10004SL | 10 | 2.7 | 880 | 110-294 | 3.0×2 | 1440 | 3 | 200-460 | 50/60 | 0.75 | 1440 | 11/21 | 4 | Ф11.2 | 12.5 | 11 |

Options And Components

Applications

Molds, machinery manufacturing, warehousing and logistics, shipbuilding, bridge construction and other industries and factories and other special purposes.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)