Description

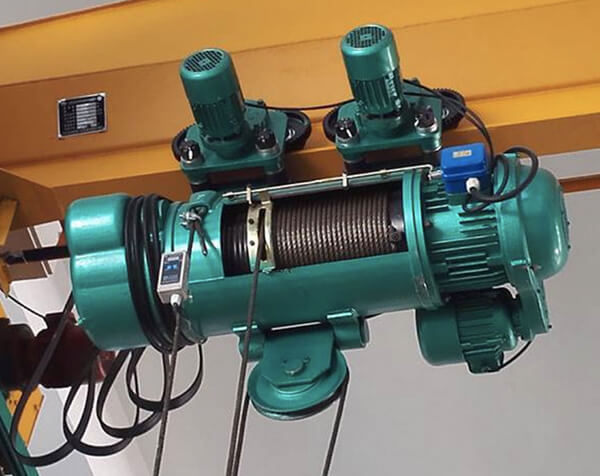

Model CD, MD wire rope electric hoist is a small size lifting equipment, which can be mounted on the single beam crane, double girder, gantry crane and arm cranes. With slight modification, it can also be used as a winch. The lifting speed of CD type electric hoist is normal speed, which can meet the general use requirements. MD electric hoist has 2 lifting speeds: normal speed and slow speed. When working at slow speed, it can meet the requirements of fine operations such as precision loading and unloading, sand box clamping machine tool maintenance, etc. Therefore, the use range of MD type electric hoist is more extensive than that of CD type electric hoist.

Features

1.Shell

Aluminum alloy shell, solid and lightweight. It has a special heat sink, which dissipates heat quickly, can be used continuously, and has an efficiency of up to 40%.

2.Break

A newly designed magnetic generator with the characteristic of producing magnetism. It can break at the same time as the power supply is cut off, so as to ensure that the brake is absolutely safe when lifting heavy loads.

3.Hook

Hot forging, high strength, not easy to break. The lower hook can be rotated 360°, and a safety tongue is attached to ensure safe operation.

Technical Data

|

CD,MD Series Electric Wire Rope Hoist(0.25T-20T) |

||||||||||||||||||||||||||

|

Type |

CD1 MD1 |

|||||||||||||||||||||||||

|

Capacity |

T |

0.25 |

0.5 |

1 |

2 |

3 |

||||||||||||||||||||

|

Lifting Height |

m |

3 |

6 |

9 |

6 |

9 |

12 |

6 |

9 |

12 |

18 |

24 |

30 |

6 |

9 |

12 |

18 |

24 |

30 |

6 |

9 |

12 |

18 |

24 |

30 |

|

|

Lifting Speed |

m/min |

8 |

8/0.8 |

8/0.8 |

8/0.8 |

8/0.8 |

||||||||||||||||||||

|

Traveling Speed |

m/min |

20(30) |

20(30) |

20(30) |

20(30) |

20(30) |

||||||||||||||||||||

|

Wire rope |

Rope d |

mm |

3.6 |

4.8 |

7.4 |

11 |

13 |

|||||||||||||||||||

|

Wire d |

Mm |

0.22 |

0.34 |

0.5 |

0.6 |

|||||||||||||||||||||

|

Structural |

6×9 |

D-6×37+1 |

D-6×37+1 |

D-6×37+1 |

D-6×37+1 |

|||||||||||||||||||||

|

track model(GB76-88) |

16-22b |

16-28b |

16-28b |

20a-32c |

20a-32c |

|||||||||||||||||||||

Options And Components

Applications

Widely used in engineering machinery, aerospace, wind power, nuclear power, automotive manufacturing, metal processing, papermaking industry and other fields

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)