Description

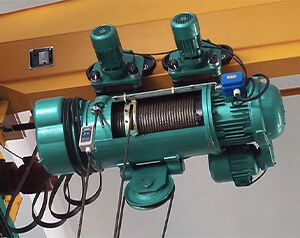

MH type electric hoist gantry crane is used together with CD MD model electric hoists. It is a track traveling small and medium-sized cranes. Its proper lifting weight is 5 to 20 tons. The proper span is 12 to 30 meters, its proper working temperature is -20°C to 40°C.

Features

1. It is a structural form welded with angle steel or I-beam, with the advantages of low cost, light weight, and good wind resistance.

2. Suitable for sites with low safety requirements and small lifting capacity.

Technical Data

|

Cart track type |

43 |

||||

|

Density of material |

t/m² |

2-3 |

2.7 |

1-2 |

0.8-0.1 |

|

Volume |

m³ |

2 |

2 |

3 |

4 |

|

Width |

b |

1460 |

1504 |

1960 |

2256 |

|

Length after opening |

L |

3200 |

3520 |

3200 |

3700 |

|

Distance between grab and operation |

a |

1502 |

1500 |

1252 |

1104 |

|

Limit size |

S₂ |

2500 |

3500 |

5000 |

|

|

S, |

5000 |

7000 |

9000 |

||

|

Max height for coal bogie |

h₁ |

6470 |

|||

|

Max.height tar coal bogie |

h |

5000 |

|||

|

Distance between handcart track and grab |

H₅ |

13262 |

13062 |

13262 |

|

|

Max.height between grab and cart track |

H₄ |

1000 |

|||

|

Distance between main beam and cart |

H₃ |

13577 |

13277 |

12977 |

|

|

Buffer unit height |

H₂ |

760 |

880 |

||

|

Distance between cart and handcart |

H₁ |

15000 |

|||

|

Conductor frame outer size |

L₃ |

10650 |

11830 |

13180 |

|

|

Right arm height |

L₂ |

9300 |

10450 |

11950 |

|

|

Left arm length |

L₁ |

7700 |

9850 |

11850 |

|

|

Crane max.height |

H |

18000 |

18040 |

18080 |

|

|

Width |

Bg |

11388 |

12388 |

||

|

Handcart wheel distance |

Bx |

3190 |

|||

|

Cart wheel distance |

B |

9500 |

8000 |

||

Options And Components

Applications

This product is a regular crane widely used at open ground and warehouses to load, unload or grab materials. It has two controlling methods, ground controlling and room controlling.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)