Description

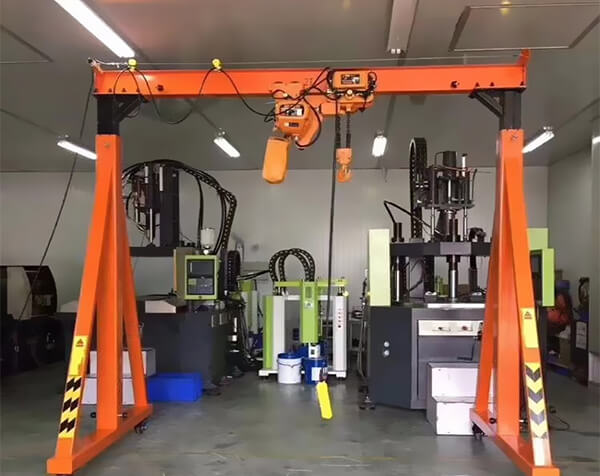

Small gantry crane is manufactured for lifting equipment, loading and unloading of the warehouse, maintaining equipment, and transporting materials, applicable for the small and medium factories.

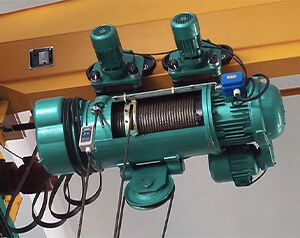

The brake-bearing universal wheel can move on the ground, and be used together with an electric hoist, chain block, or monorail trolley, realizing crane mechanization, which can reduce the human power, and production costs, and improve work efficiency. Warehouse, workshop, auto repair shops, vessels, laboratory for light weight material handling and limited working space.

Features

- Small Gantry Crane has the characteristics of being lightweight and flexible, and can be moved by its own power or trailer to meet the needs of different workplaces.

- The small mobile gantry crane is equipped with operation control equipment, such as a control console or remote control, which can achieve precise lifting and handling operations. Operators can control the lifting and lowering, forward and backward movement, and lateral expansion and contraction of the crane by controlling the equipment.

Technical Data

|

Type |

Mobile portable gantry crane |

|

Lifting capacity |

0.5—10ton |

|

Lifting height |

3—15m or customized |

|

Span |

3—10m or customized |

|

Hoisting speed |

3—8m/min or customized |

|

Working class |

A3 |

|

Working temperature |

—20∼40℃ |

|

Lifting method |

Electric or manual |

|

Painting |

Yellow, white, red or customized |

|

Application area |

Factory, workshop, warehouse, Small equipment installation, goods and work piece handing. |

|

Power supply |

AC 380V 50hz or customized |

Options And Components

Applications

The small gantry crane is a regular crane widely used at open ground and warehouses to load, unload or grab materials. It has two controlling methods, ground controlling and room controlling.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)