Description

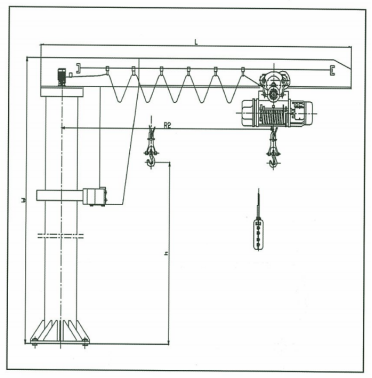

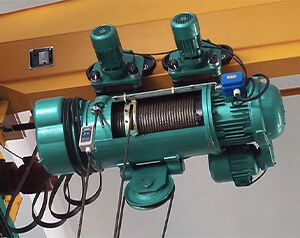

This kind of floor mounted jib crane normally works with electric wire rope hoist or electric chain hoist, which consists of fixed column, rotating arm, rotation drive mechanism and electric hoist. The column is fixed on the concrete foundation by anchor bolt.

The motor drives the driving mechanism to make the cantilever rotate. Electric hoist travelling on the jib beam .

It belongs to Light & Middle working class, with lifting load 0.25t, 0.5t, 1t, 2t, 3t, 5t, larger capacity can custom made.

The rotation angle 360°which can meet different kind of using environment.

Features

- Cut Down your cost in building of plant and workshop

- Suitable for different operating conditions, improving production efficiency

- Specially design and customize products according to your needs.

- Compact structure, excellent performance, high efficiency, time and effort saving.

Technical Data

|

Model |

Lifting weight |

Hoisting speed (CD wire rope hoist) |

Rotation speed(r/min) |

Arm length L(mm) |

R2(mm) |

R1(mm) |

H(mm) |

h(mm) |

|

ZB-A0.25-D/S |

0.25T |

8(m/min) |

0.92 |

5425 |

5000 |

1000 |

5100 |

4000 |

|

ZB-A0.5-D/S |

0.5T |

0.92 |

5425 |

5000 |

1000 |

5100 |

4000 |

|

|

ZB-A1-D/S |

1T |

0.76 |

5500 |

5000 |

1000 |

5100 |

4000 |

|

|

ZB-A2-D/S |

2T |

0.76 |

3765/5565/6525 |

3300/5000/6000 |

1300/1300/1500 |

4350/5400/4660 |

3000/4000/3500 |

|

|

ZB-A3-D/S |

3T |

0.59 |

5560 |

5000 |

1500 |

3150 |

3500 |

|

|

ZB-A5-D/S |

5T |

0.51 |

4680 |

4000 |

1800 |

4770 |

3000 |

Options And Components

Applications

Manufacturing workshop, metallurgy, petroleum, petrochemicals, ports, railway, civil aviation, power station, food industry, paper making, building material, warehouses and other material handling application.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)