Description

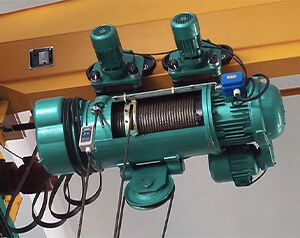

This type of wall mounted jib crane provides 0-180 degrees of rotation and can be easily mounted on any substantial steel structure building column at any desired height. Wall Jib crane mainly used on the walls of workshop. This kind of crane can be used to match with single or double speed electric hoist and chain hoist.

Features

- It can be mounted to your wall to accommodate any space constraints.

- Load capacity from 0.25t to 5t.

- Easy to operate, safe, flexible steering.

- This Wall Mount Jib Crane utilize 180 degree floor coverage, allowing unrestricted placement of machinery and equipment.

Technical Data

|

Capacity – t |

0.25-5 |

|

Lift height – m |

3-10 |

|

Radius – m |

2-6 |

|

Lift speed – m/min |

8 |

|

Traveling – m/min |

20 |

|

Rotation Speed-m/min |

0.76-0.53 |

|

Rotation – degree |

180 |

|

Control way |

Pendent / Remote Control |

|

Working temperature |

-20~+40℃ |

Options And Components

Applications

Manufacturing workshop, metallurgy, petroleum, petrochemicals, ports, railway, civil aviation, power station, food industry, paper making, building material, warehouses and other material handling application.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)