Description

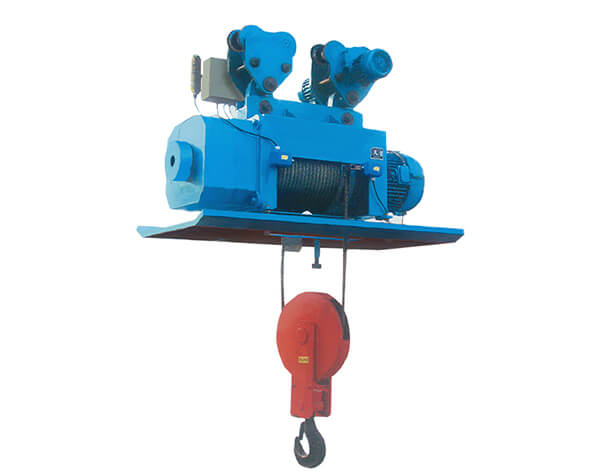

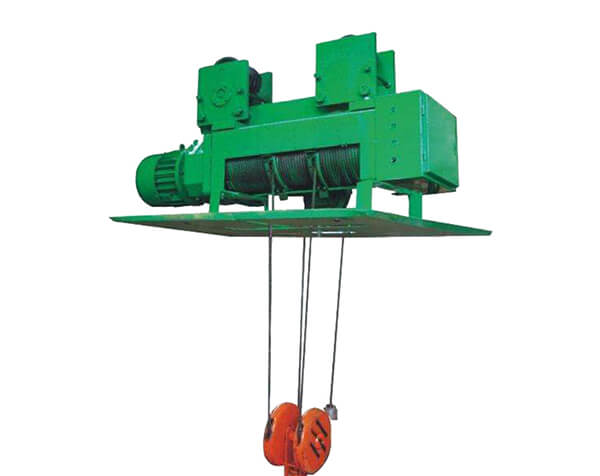

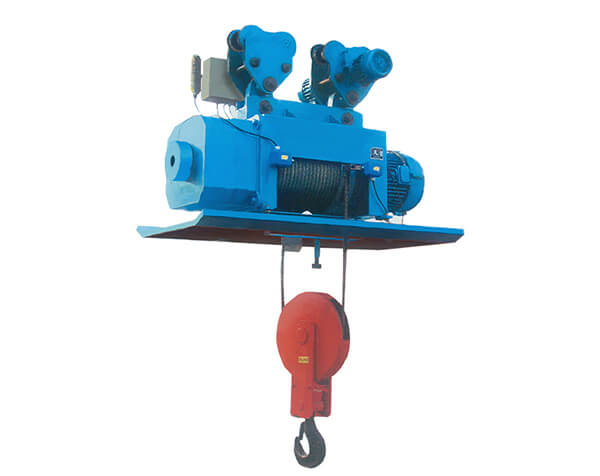

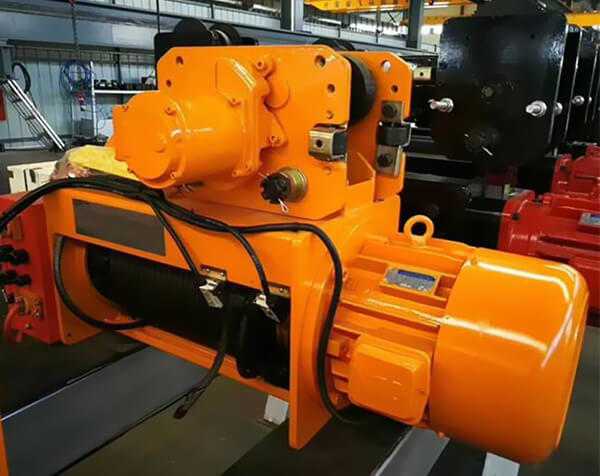

Metallurgical electric hoist, also known as molten metal electric hoist, is generally installed on the I-beam track to lift heavy objects, and can make a straight line along the track, curve reciprocating motion, to ensure sufficient safety. It is suitable for working in an environment without fire, explosion hazard and corrosive medium, suitable for lifting molten metal and its operation in dangerous places, and the double brake is not allowed to disassemble a brake.

Metallurgical electric hoist mainly used for lifting molten metal.

Features

1. This series of products can be used to lift molten metal, but it is forbidden to use it in a low temperature environment below 10C or above 50*C, in an explosion hazard, full of sulfuric acid and corrosive gases, and in a place where toxic and flammable substances are hoisted, so as to ensure safety and reliability.

2. The electric wire rope hoist for metallurgy has added one safety brake directly set on the drum to achieve the safety of the lifting product

3. It can make straight lines and reciprocating movements along the track to ensure sufficient safety

Technical Data

|

YJCD, YJMD Series Electric Wire Rope Hoist(0.25T-20T) |

||||||||||||||||||||||||||

|

Type |

YJCD1 YJMD1 |

|||||||||||||||||||||||||

|

Capacity |

T |

0.25 |

0.5 |

1 |

2 |

3 |

||||||||||||||||||||

|

Lifting Height |

m |

3 |

6 |

9 |

6 |

9 |

12 |

6 |

9 |

12 |

18 |

24 |

30 |

6 |

9 |

12 |

18 |

24 |

30 |

6 |

9 |

12 |

18 |

24 |

30 |

|

|

Lifting Speed |

m/min |

8 |

8/0.8 |

8/0.8 |

8/0.8 |

8/0.8 |

||||||||||||||||||||

|

Traveling Speed |

m/min |

20(30) |

20(30) |

20(30) |

20(30) |

20(30) |

||||||||||||||||||||

|

Wire rope |

Rope d |

mm |

3.6 |

4.8 |

7.4 |

11 |

13 |

|||||||||||||||||||

|

Wire d |

Mm |

0.22 |

0.34 |

0.5 |

0.6 |

|||||||||||||||||||||

|

Structural |

6×9 |

D-6×37+1 |

D-6×37+1 |

D-6×37+1 |

D-6×37+1 |

|||||||||||||||||||||

|

track model(GB76-88) |

16-22b |

16-28b |

16-28b |

20a-32c |

20a-32c |

|||||||||||||||||||||

Options And Components

Applications

The metallurgical electric hoist is installed on the I-beam track to lift heavy objects, and can make a straight line and curve reciprocating motion along the track to ensure sufficient safety. It is suitable for working in an environment without fire, explosion hazard and corrosive medium, suitable for lifting molten metal and its operation in dangerous places, and the double brake is not allowed to disassemble a brake.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)