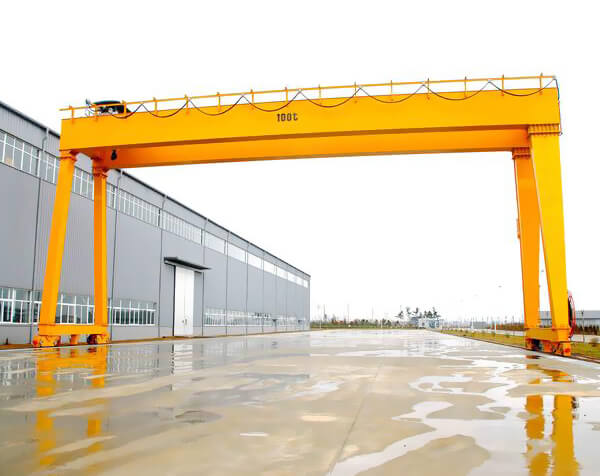

Description

The European-style gantry crane is designed and manufactured according to the advanced standards of European Standard Co., Ltd. Its rated capacity is 3 ~ 20t. The lifting mechanism is a European-style electric hoist trolley. The trolley is equipped with a reducer and a three-in-one transmission.

The use of variable frequency speed regulation technology comprehensively improves the overall performance of the product. The weight of the entire machine is reduced by more than 15%, and the wheel pressure is 10 to 20%.This product can be widely used in factories, freight yards, warehouses and other places where goods are loaded and unloaded.

Features

- Strong carrying capacity, suitable for large and heavy objects. It has good stability and is suitable for occasions requiring large-scale lateral movement.

- Light weight

- European finite element advanced standard design

- Three-level drive, high work efficiency

- Frequency conversion speed regulation technology

Technical Data

| Capacity (ton) | 5 | 10 | 16/3.2 | 20/5 | 32/5 | 50/10 | |

| Span (m) | 18,22, 24, 26, 30, 35 | ||||||

| Lifting height (m) | 10.11,12 | ||||||

| Working class | A5 | ||||||

| Control way | Cabin control or remote control | ||||||

| Power source | 380V 50HZ 3phase (Could supply it as yours) | ||||||

| Trolley lifting mechanism | |||||||

| LUfting speed (m/min) | Main hook | 11.3 | 8.5 | 7.9 | 7.2 | 7.5 | 5.9 |

| Auxlliary hook | - | - | 14.6 | 15.4 | 15.4 | 10.4 | |

| Trolley traveling mechanism | |||||||

| Traveling speed (m/min) | 37.3 | 35.6 | 36.6 | 36.6 | 37 | 36 | |

| Crane traveling mechanism | |||||||

| Traveling speed (m/min) | 37.3 | 39.7 | 37.3 | 39.7 | 39.4 | 38.5 | |

| Motor power(Kw) | 40.8-51.8 | 41.5-52.8 | 80-77 | 84-81 | 99.3-117.3 | 126.5 | |

| Steel track recommended | 43kg/m | 43kg/m or QU70 | |||||

Options And Components

Applications

This crane is widely applied to do loading and unloading work in outdoor. Such as material stocks area, cement plant, granite industry, construction industry, and engineering industry and so on. It has features of beautiful and durable appearance, perfect performance, low cost, easy maintenance, high adaptability and so on.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)