Description

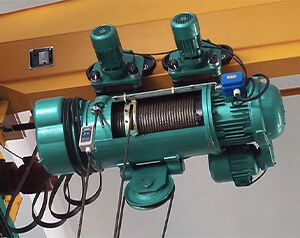

LDA Type Electric Single Beam Crane refers to a type of crane where the track is overhead and the main beam of the crane moves back and forth on the overhead track. The electric hoist is hung on the main beam of the crane and moves left and right along the main beam. The electric hoist hook is used to lift and lift heavy objects.

LDA Type Electric Single Beam Crane are also collectively referred to as overhead cranes, gantry cranes, overhead cranes, and overhead cranes. The work level is usually A3.

Features

- LDA type electric single beam crane has the characteristics of reasonable structure and strong rigidity. The whole machine is used together with CD type, MD type and HC type electric hoist.

- It is a kind of light and small-sized lifting machinery with lifting weight capacity 1t-20t, and span from 7.5m ~ 31.5m, the working grade is A3, and the working environment temperature is – 25 ℃ to 40 ℃. LDA Type 1~20T Electric Single Beam Crane widely used in plants, warehouse, material stocks to lift goods. It is prohibit to use in the combustible, explosive or corrosives environment

Technical Data

| (t) Lifting weight |

(m) S span |

G(t) total weight ground control |

Rmax(KN) Max wheel load |

Rmin(KN) min wheel load |

H1 Wheel tread approach to top |

H2 Wheel tread approach to center of hook |

H3 Total height of main girder |

B End carriage wheelbase |

BQ Total length of end carriage |

C1 Hook approach to limit position on the left |

C2 Hook approach to limit position on the right |

| 5 | 7.5 | 2.20 | 28.7 | 4.6 | 580 | 1640 | 720 | 2000 | 2500 | 841.5 | 1310 |

| 8 | 2.27 | 29.0 | 4.7 | ||||||||

| 8.5 | 2.33 | 29.3 | 4.9 | ||||||||

| 9 | 2.40 | 29.7 | 5.0 | ||||||||

| 9.5 | 2.46 | 30.0 | 5.2 | ||||||||

| 10 | 2.53 | 30.2 | 5.3 | ||||||||

| 10.5 | 2.59 | 30.5 | 5.5 | ||||||||

| 11 | 2.66 | 30.8 | 5.6 | ||||||||

| 11.5 | 2.91 | 31.5 | 6.3 | 660 | 800 | ||||||

| 12 | 2.98 | 31.8 | 6.4 | ||||||||

| 12.5 | 3.05 | 32.0 | 6.6 | ||||||||

| 13 | 3.12 | 32.3 | 6.8 | ||||||||

| 13.5 | 3.20 | 32.5 | 6.9 | ||||||||

| 14 | 3.27 | 32.8 | 7.1 | ||||||||

| 14.5 | 3.52 | 33.5 | 7.7 | 785 | 1635 | 920 | 2500 | 3000 | |||

| 15 | 3.60 | 33.7 | 7.9 | ||||||||

| 15.5 | 3.68 | 33.9 | 8.1 | ||||||||

| 16 | 3.75 | 34.2 | 8.3 | ||||||||

| 16.5 | 3.83 | 34.4 | 8.5 | ||||||||

| 17 | 3.90 | 34.6 | 8.7 | ||||||||

| 17.5 | 4.41 | 35.9 | 9.9 | 880 | 1620 | 1000 | |||||

| 18 | 4.50 | 36.2 | 10.2 | ||||||||

| 18.5 | 4.59 | 36.5 | 10.4 | ||||||||

| 19 | 4.68 | 36.7 | 10.6 | ||||||||

| 19.5 | 4.76 | 37 | 10.8 | ||||||||

| 20 | 5.23 | 38.2 | 12.0 | 920 | 1700 | 1120 | 3000 | 3500 | |||

| 20.5 | 5.33 | 38.4 | 12.2 | ||||||||

| 21 | 5.42 | 38.7 | 12.4 | ||||||||

| 21.5 | 5.51 | 38.9 | 12.7 | ||||||||

| 22 | 5.60 | 39.2 | 12.9 | ||||||||

| 22.5 | 5.70 | 39.5 | 13.1 | ||||||||

| 23 | 7.08 | 42.9 | 16.6 | 960 | 1740 | 1200 | 3500 | 4000 | |||

| 23.5 | 7.20 | 43.2 | 16.9 | ||||||||

| 24 | 7.32 | 43.6 | 17.2 | ||||||||

| 24.5 | 7.43 | 43.9 | 17.4 | ||||||||

| 25 | 7.55 | 44.2 | 17.7 | ||||||||

| 25.5 | 7.67 | 44.5 | 18.0 | ||||||||

| 26 | 9.01 | 47.9 | 21.4 | 1200 | 1700 | 1400 | 3500 | 4000 | |||

| 26.5 | 9.16 | 48.3 | 21.7 | ||||||||

| 27 | 9.30 | 48.6 | 22.1 | ||||||||

| 27.5 | 9.44 | 49.0 | 22.5 | ||||||||

| 28 | 9.58 | 49.4 | 22.8 | ||||||||

| 28.5 | 9.72 | 49.7 | 23.2 |

Options And Components

Applications

This product is a regular crane widely used at open ground and warehouses to load, unload or grab materials. It has two controlling methods, ground controlling and room controlling.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)