Description

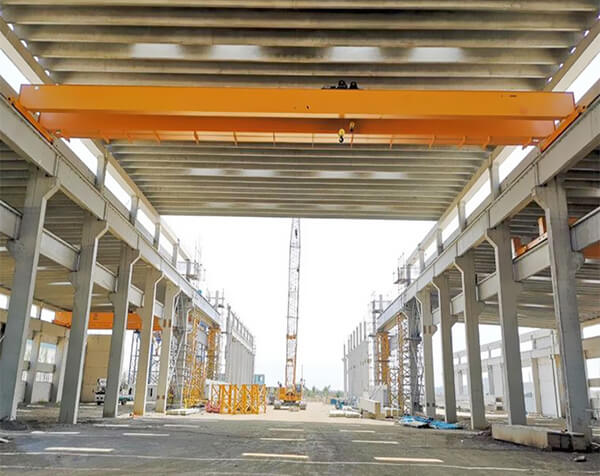

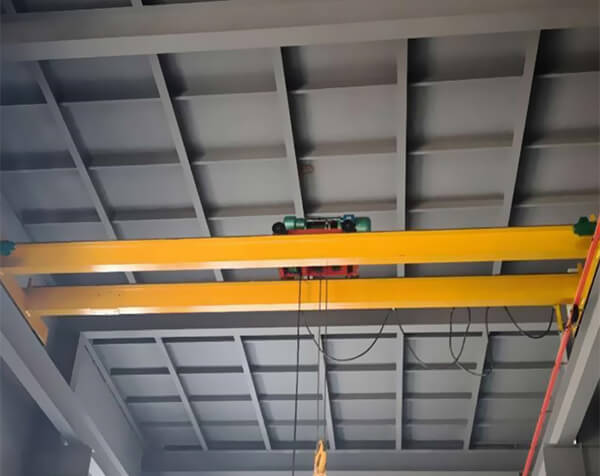

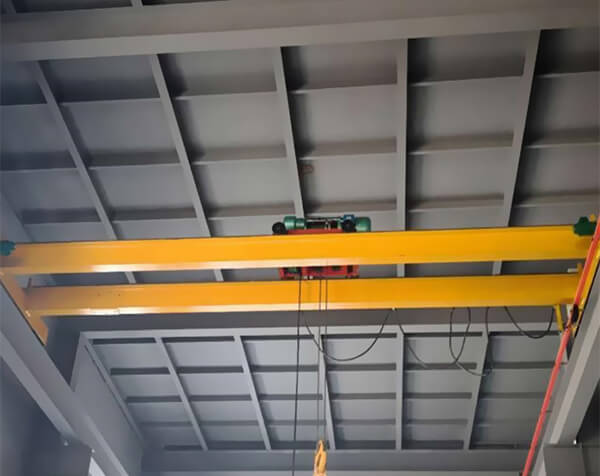

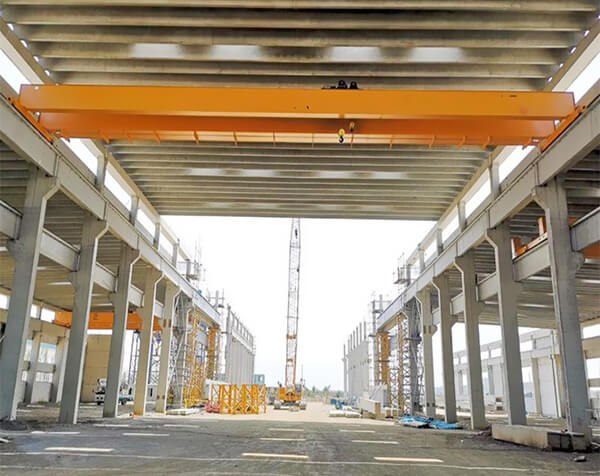

LH Type Electric Hoist Bridge Crane is a bridge crane that uses a fixed steel wire rope hoist as the lifting mechanism, installed on a centrally driven double track trolley, and used in conjunction with the double beam bridge. It has the advantages of compact external dimensions, low building clearance height, light self weight, and low wheel pressure. It is an economical, practical, reliable, and easy to operate lifting equipment. The LH type hoist double beam crane is mainly suitable for the operation, assembly, maintenance, and loading and unloading operations of machinery manufacturing workshops, warehouses, material yards, power stations, etc. It can complete various transportation, assembly, maintenance, and loading and unloading operations.

Features

- The LH electric hoist bridge crane is suitable for working in working levels A3 to A4, working environments with temperatures ranging from -25 ℃ to+40 ℃, and environments without flammable, explosive, or corrosive media. The lifting capacity is 3-63 tons, with a span of 7.5-31.5 meters.

- The power supply of the crane is three-phase AC, with a rated frequency of 50Hz or 60Hz. The rated voltage is between 220V and 660V. The upper limit of allowable voltage fluctuations on electric motors and appliances is+10% of the rated voltage, and the lower limit (during peak voltage) is -15% of the rated voltage. The internal voltage loss of the crane shall not exceed 3%.

Technical Data

|

Capacity |

t |

3~20 |

|

|

Span |

m |

10.5-31.5 |

|

|

Lifting height |

m |

6~18 |

|

|

Speed |

Lifting |

m/min |

8,8/0.8, 7,7/0.7 3.5,3.5/0.35 |

|

Cross travel |

m/min |

20,30 |

|

|

Electric hoist |

type |

CD/MD/HC |

|

|

Working duty |

A3, A4 |

||

|

Power supply |

AC |

380V/50HZ/3P or Customized |

|

Options And Components

Applications

This product is a regular crane widely used at open ground and warehouses to load, unload or grab materials. It has two controlling methods, ground controlling and room controlling.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)