Description

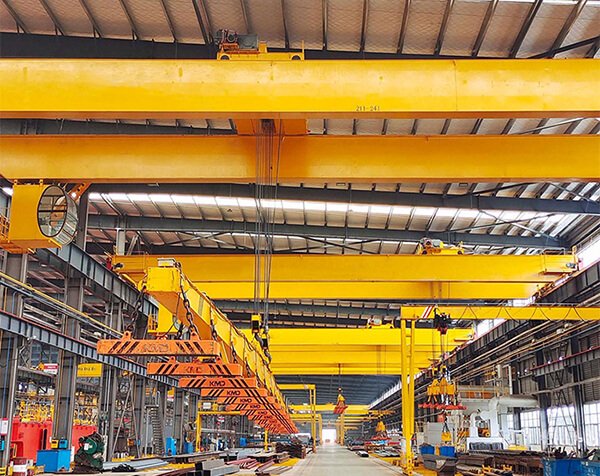

QC Type Electromagnet Bridge Crane is mainly equipped with electromagnet, When the current is turned on, the electromagnet will firmly attract the steel objects and lift them to the designated place. Cut off the current, the magnetism disappeared, and the steel object was put down. The crane is suitable for scrap recycling plants and steel mills.

Features

1. The QC type electromagnetic double beam crane has the characteristics of simple structure, convenient operation, and easy maintenance. It adopts a double beam structure, which can bear a large weight while also achieving lateral movement and up and down lifting. In addition, the QC type electromagnetic double beam crane is also equipped with electromagnetic suction cups, which can achieve adsorption and suspension of objects of various shapes, improving lifting efficiency

2. QC type electromagnetic double beam cranes are widely used in various industrial fields. It can be used on production lines in industries such as steel, machinery, shipbuilding, automobiles, and aviation, as well as for cargo loading and unloading in ports, docks, warehouses, and other places. In addition, the QC type electromagnetic double beam crane can also be used for various lifting operations on construction sites, such as lifting steel bars, concrete components, etc

3. Safety precautions should be taken during the use of QC type electromagnetic double beam cranes. Operators should be familiar with the usage methods and operating procedures of the equipment, strictly abide by safety operation regulations, and ensure the safety and stability of lifting operations. At the same time, the maintenance and upkeep of the equipment is also very important. Regular inspections of various components of the equipment are necessary to promptly detect and handle faults, ensuring the normal operation of the equipment

Technical Data

|

Lifting weight |

MT |

5Ton |

10Ton |

|||||||||||||||

|

Span |

m |

10.5 |

13.5 |

16.5 |

19.5 |

22.5 |

25.5 |

28.5 |

31.5 |

10.5 |

13.5 |

16.5 |

19.5 |

22.5 |

25.5 |

28.5 |

31.5 |

|

|

Lifting Height |

m |

16M |

||||||||||||||||

|

Working level |

A6 |

|||||||||||||||||

|

Speed |

Lifting |

m/min |

19.9m/min |

19.4m/min |

||||||||||||||

|

Trolley Runing |

39.5m/min |

43.8m/min |

||||||||||||||||

|

Trolley Runing |

115.6m/min |

116.8m/min |

115.6m/min |

116.8m/min |

12.5m/min |

|||||||||||||

|

Motor |

Lifting |

Model |

YZR180-6/15kw |

YZR250M 1-6/30kw |

||||||||||||||

|

Trolley Runing |

YZR112M 2-6/1.5kw |

YZR132M 1-6/2.2kw |

||||||||||||||||

|

Trolley Runing |

YZR160M 1-6/2×5.5kw |

YZR160M 2-6/2×7.5kw |

YZR160M 1-6/2×5.5kw |

YZR160M 2-6/2×7.5kw |

||||||||||||||

|

Size |

B |

5390 |

5450 |

6100 |

6040 |

6130 |

6330 |

|||||||||||

|

W |

3600 |

3660 |

5000 |

4250 |

4200 |

5000 |

||||||||||||

|

Wx |

1100 |

1500 |

||||||||||||||||

|

b |

230 |

|||||||||||||||||

|

K |

1400 |

1500 |

2000 |

|||||||||||||||

|

H |

1764 |

2028 |

2026 |

2076 |

||||||||||||||

|

H 1 |

2526 |

2546 |

2596 |

2756 |

2906 |

3056 |

6206 |

3356 |

2528 |

2548 |

2598 |

2758 |

2908 |

3008 |

3158 |

3308 |

||

|

H 2 |

735 |

|||||||||||||||||

|

F |

122 |

126 |

226 |

376 |

526 |

676 |

826 |

976 |

122 |

128 |

228 |

378 |

528 |

628 |

778 |

928 |

||

|

L 1 |

1250 |

1500 |

||||||||||||||||

|

L 1 |

1500 |

|||||||||||||||||

|

Maximum wheel pressure |

kN |

71 |

77 |

85 |

92 |

102 |

112 |

120 |

131 |

113 |

120 |

126 |

135 |

142 |

154 |

161 |

170 |

|

|

Recommended steel |

38kg/m |

43kg/m |

||||||||||||||||

|

Power |

3P 380v 50Hz |

|||||||||||||||||

|

Lifting electromagnet |

Model |

MW 1-6 |

MW 1-6 |

MW 1-6 |

||||||||||||||

|

Lifting weight |

kg |

4540kg |

3330kg |

8330kg |

||||||||||||||

|

Self weight |

kg |

460kg |

1670kg |

1670kg |

||||||||||||||

|

Diameter |

mm |

776mm |

1180mm |

1180mm |

||||||||||||||

Options And Components

Applications

This product is a regular crane widely used at open ground and warehouses to load, unload or grab materials. It has two controlling methods, ground controlling and room controlling.

Service

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

2. Replacement of damaged components (non-human-induced) is provided during the warranty period.

2. Safety and Compliance Support: Ensure that their products comply with local and international safety and regulatory standards, and provide relevant documentation and support.

2. We will send professional Chinese crane installation team or find local crane installation team according to the product plan and customer demand, to ensure that the product can be used safely and effectively.

-600x476.jpg)